At the end of last semester, I took my graduate level course on stochastic processes for a tour of the Babcock Dairy Hall, a campus dairy facility that makes numerous dairy products and has an observation deck for viewing. Cheese inspired my midterm exam, and we wanted to learn more about cheese and industrial engineering.

It turns out that making cheese draws upon industrial engineering methodologies in a big way.

Main challenge: variable prices and variable demand

The price of milk is variable. Cheese makers buy milk now, but the selling price after the cheese has aged is based on future milk prices. So cheese makers must forecast selling prices and work their way backward to schedule production now (I have more on cheese forecasting later, too). Cheese ages from months to years, so they look fairly far into the future. To complicate matters, they do not know the price of milk now. They are billed a month after they purchase and then must correct their forecast error.

It was somewhat surprising that the decisions are made quickly. The milk must be processed within 24 hours of when it is purchased. This rules out the possibility to stockpile milk when it is cheap to address rising forecasts, spikes in demand, etc.

The cost of milk isn’t the only cost. The other (and only other) major cost is labor cost. At a small scale cheese plant like that at UW-Madison, labor represents a larger share of cheese cost than what is typical. This is because the UW’s cheese plant is flexible and non-specialized, both of which hinder the use of automation to keep costs down.

Matching supply and demand

Another interesting challenge is that there is a craft to matching supply and demand. Demand for cheese is very cyclic and somewhat predictable from what I’ve been told. Still, the forecasting process is not perfect. There is a window for selling cheese that is approximately 3-6 months. After this point, the cheese is not as fresh. The Babcock Dairy Hall sometimes sells cheese at 20% off to increase demand and reduce their inventory of cheese that is getting close to the end of its freshness window. I got the impression that other pricing strategies was an area of interest.

Finding the right mix of cheese

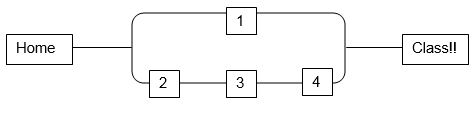

There are two main types of constraints for scheduling cheese production. The first is scheduling how cheese is made. The cheese makers at the Babcock Dairy Hall typically make one type of cheese per day. Some types of cheese like cheddar are so popular that they might be made every week. The second constraint is scheduling how cheese is stored. The huge refrigerator for aging cheese is almost always near its capacity. Different types of cheese are aged at different times. Take cheddar for example. Mild cheddar is aged three months whereas extra sharp is aged for two years. The recipes are different, so the cheese makers do not use the same batch of cheddar to make mild and extra sharp simply by aging it longer. Storing too much extra sharp cheddar would not leave enough room for havarti or Colby. This reminded me of a linear programming problem I once saw about wine production, where a wine maker had to use a limited number of barrels to make the right mix of red and white wine. And yes, I will certainly ask a question about finding the optimal cheese mix when I teach introductory linear programming.

Everything works perfectly until you experiment with new cheese

If a cheese is popular and sells out quickly, it is not possible to ramp up production and instantly meet demand, as can be done for ice cream, which is made one day and eaten the next. The Dutch Kase cheese ended up extremely popular and selling out quickly. The problem was that it takes 18 months to age, and therefore, customers were irate as they waited for cheese. Forecasting the demand for new cheese is close to impossible. I’m not sure what can be done here. Everyone loving a new type of cheese is a good problem to have. The Babcock Dairy Plant experiments with new products all the time. Lately, they have been pushing lactose free ice cream (yeah!!), which I hope they continue for people like me who are lactose challenged.

Other issues are scheduling cleaning (a minimum of 2.5 hours per day), quality control tests, and taste tests (expert tasters cannot taste too much cheese in one sitting or it all tastes the same).

From linear programming to forecasting and pricing and manufacturing, industrial engineering is important for making cheese.